V9:Armor Styles

Developer Note: The current V9 Rules can be found here.

The V9 Wiki is currently obsolete. The Project Phoenix Google Doc is the main source of V9 rules going forward.

We will eventually rebuild the wiki as a comprehensive rules reference, but now is not that time.

Thank you for your interest in the project! Join the Discord for more information!

- The Project Phoenix (V9) Development Team

Contents

Armor Styles

Each Armor Tier includes a list of common Armor Styles that fall under that tier. Those styles are presented here in greater detail to help players and inspectors more accurately assess their armor. Ambiguous armor pieces should be assessed on a case-by-case basis.

| ARMOR TIERS | |||

|---|---|---|---|

| TIER | BASE RATING |

MAX RATING |

INCLUDES |

| T1 | 1 | 2 | |

| T2 | 2 | 3 | |

| T3 | 3 | 4 | |

| T4 | 4 | 5 | |

| T5 | 5 | 6 | |

| T6 | 6 | 7 | |

| Special | - | - | |

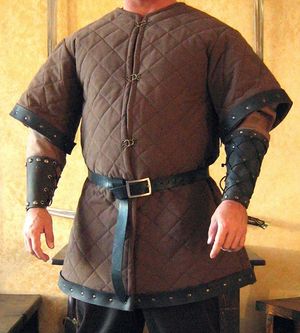

Cloth/Padded Armor

This style includes armor made of fabric, padding, and/or synthetic equivalents.

- Is a Tier 1 armor style.

- Must meet the Universal Equipment Requirements.

- Minimum Material Thickness of 1/16" (1.60mm)

Light Leather

This style includes armor made of thin leather, hides, furs and their synthetic equivalents.

- Is a Tier 2 armor style.

- Must meet the Universal Equipment Requirements.

- The standard Material Thickness is 6oz (3/32") (2.39mm).

Butcher's Mail, Sharkmail, etc

This style includes armor composed of machine-made weaves of very small rings.

- Is a Tier 2 armor style.

- Must meet the Universal Equipment Requirements.

- Only welded Butcher's Mail, Sharkmail, Ringmesh, or similar chain mesh may be used. Because of this, there are no specific Material Thickness requirements or modifiers.

- Any weave is permitted but it must not allow a 1/8" dowel to pass through

- Does not gain a bonus for being made from Steel or similar metal.

Heavy Leather

This style includes armor made of thick leather, hides, furs and their synthetic equivalents.

- Is a Tier 3 armor style.

- Must meet the Universal Equipment Requirements.

- The standard Material Thickness is 10oz (5/32") (3.96mm).

Rigid Non-Metal Armor

This style includes all predominantly rigid non-metal armor that would fall under Tiers 4/5/6 if they were made from metal.

- Is a Tier 3 armor style.

- Must meet the Universal Equipment Requirements.

- Must meet the requirements for the tier/style it is mimicking, other than material thickness.

- Material density must be at least 0.9g/cm3 (equivalent to HDPE).

- The standard Material Thickness is 3/16" (4.78mm).

Chainmail

This style includes flexible armor consisting of a weave of interlocked metal rings.

- Is a Tier 3 armor style.

- Must meet the Universal Equipment Requirements.

- Any weave is permitted but it must not allow a 1/2" dowel to pass through.

- Rings must have Aspect Ratio (AR) of 8 or less.

- Metal must be at least equivalent to Aluminum in density and durability. (2.7g/cm3)

- The standard Material Thickness for rings is based on the metal used:

- Aluminum Round Rings: 16ga swg (0.064") (1.626mm)

- Aluminum Flat Rings: 18ga swg (0.048") (1.219mm)

- Steel Round Rings: 18ga swg (0.048") (1.219mm)

- Steel Flat Rings: 20ga swg (0.036") (0.914mm)

Light Scale

This style includes armor created with overlapping scales secured to each other along one edge using rings or a flexible backing. Scales are individually mobile and are not held into firm contact with the others. Scale armor with rigid or immobile scales is classified as Heavy Scale.

- Is a Tier 4 armor style.

- Must meet the Universal Equipment Requirements.

- Scales must overlap by at least 10%.

- Any backing material must not be visible through the scales.

- Scales must be a metal at least equivalent to Aluminum in density and durability. (2.7g/cm3)

- The standard for Material Thickness is based on the metal used:

- Aluminum Scales: 18ga (0.040") (1.024mm)

- Steel Scales: 20ga (0.036") (0.911mm)

- For rings and backing materials, consult the Material Thickness chart.

Heavy Scale

This style includes armor created with overlapping scales secured to each other along one edge against a backing to create a rigid shell rather than individually mobile scales. Scale armor with loose scales is classified as Light Scale.

- Is a Tier 5 armor style.

- Must meet the Universal Equipment Requirements.

- Scales must overlap by at least 10%.

- The backing material must not be visible through the scales.

- Metal must at least equivalent to Aluminum in density and durability. (2.7g/cm3)

- The standard for Material Thickness is based on the metal used:

- Aluminum Scales: 18ga (0.040") (1.024mm)

- Steel Scales: 20ga (0.036") (0.911mm)

- For rings and backing materials, consult the Material Thickness chart.

Butted Plate (Splint, Kikko, etc.)

This style includes armor that consists of numerous metal plates attached to a backing or linked by cord, chain, or by some other method. This armor is often flexible with numerous seams and joints between plates. This armor will deform locally when struck rather than spreading out impact over a large area

- Is a Tier 5 armor style.

- Must meet the Universal Equipment Requirements.

- Plates spaced no more than 0.5" apart.

- Plates must cover at least 75% of the armor.

- Metal must at least equivalent to Aluminum in density and durability. (2.7g/cm3)

- The standard for Material Thickness is based on the metal used:

- Aluminum Plates: 16ga (0.051") (1.291mm)

- Steel Plates: 18ga (0.048") (1.214mm)

- For rings and backing materials, consult the Material Thickness chart.

Lamellar and Laminar

This style includes armor that is constructed from numerous metal plates, connected to each other in an overlapping fashion by cord, chain link, or similar methods. Examples may include lorica segmentata, manica, okegawa-dō, anima, and other styles. Unlike Heavy Scale, the plates of this type of armor are firmly connected to each other. Mobility is provided by the small amount of flex and slack in the attachment between the individual plates.

- Is a Tier 6 armor style.

- Must meet the Universal Equipment Requirements.

- Plates must overlap by at least 10%.

- Plates connect directly to each other without any backing for support.

- Metal must at least equivalent to Aluminum in density and durability. (2.7g/cm3)

- The standard for Material Thickness is based on the metal used:

- Aluminum Plates: 16ga (0.051") (1.291mm)

- Steel Plates: 18ga (0.048") (1.214mm)

Brigandine

This style includes armor that is constructed from numerous shaped and fitted metal plates solidly connected along a supporting shell of heavy cloth (such as canvas, denim, or velvet) in such a way that when worn all plates are held together firmly and follow the general contours of the body. The plates are typically placed on the inside of the shell, presenting only fabric and rivets to the observer for a very clean and customizable appearance.

- Is a Tier 6 armor style.

- Must meet the Universal Equipment Requirements.

- 75% of plates must overlap by at least 10% of their surface.

- Plates need only be attached along one edge but must be held firmly against each other when the armor is worn.

- Metal must at least equivalent to Aluminum in density and durability. (2.7g/cm3)

- The standard for Material Thickness is based on the metal used:

- Aluminum Plates: 16ga (0.051") (1.291mm)

- Steel Plates: 18ga (0.048") (1.214mm)

Plate

This style includes armor is constructed from large pieces of metal connected together to form a solid shell that spreads impact over a large surface area. Plate armor will not deform locally when struck, and will instead behave as a single contiguous whole. The individual metal pieces are shaped and fitted to articulate together and follow the contours of the body.

- Is a Tier 6 armor style.

- Must meet the Universal Equipment Requirements.

- 75% of the plates used must be large enough to cover at least 10% of the full Hit Location. Joint articulations are exempt from this requirement.

- Metal must at least equivalent to Aluminum in density and durability. (2.7g/cm3)

- The standard for Material Thickness is based on the metal used:

- Aluminum Plates: 16ga (0.051") (1.291mm)

- Steel Plates: 18ga (0.048") (1.214mm)

Ambiguous Armor

For armor pieces that are ambiguous, the equipment inspector should compare it to each tier as a whole and do their best assign to the tier they feel is most appropriate based on factors such as materials, weight, flexibility, and visuals (see guide below).

- Inspectors should reference similar styles and materials to help gauge what bonuses or penalties may be appropriate.

- Ambiguous Armor must still meet the Universal Equipment Requirements.

Below is a simple guide that inspectors may use to gauge the best tier for an ambiguous piece of armor. Use this knowledge alongside existing styles to help place the armor in a tier that is fair for everyone.

- Non-Metal Tier Cap: Non-metal armors should not be placed higher than Tier 3, regardless of the factors below.

- Weight: Heavier armor should be placed higher, but only to a limit. The lowest tier armors are quilted cloth (0.03 lbs/sqft) and the highest tier armors are 14ga aluminum plate (approx. 1 lbs/sqft). Extra weight beyond these bounds should receive no additional consideration, however steel-like materials may receive a separate construction bonus afterwards. Weight added for no reason other than to add weight should likewise be disregarded.

- Flexibility: The more rigid the armor is, the higher it should be placed. The lowest tier armors are fabric and the highest tier armors are reinforced metal plates.

- Tiebreaker - Visuals: If there is difficulty deciding between two tiers, visual appearance can act as a tiebreaker to nudge the decision one way or the other.

- Helpful Benchmarks: Consider using these benchmarks to help peg an initial placement and then fine tune it using the other criteria above.

- Ambiguous armor that meets the universal equipment requirements is always eligible for Tier 1 at minimum.

- Ambiguous armor that is primarily rigid and non-metal should be placed roughly around Tier 2 or Tier 3.

- Ambiguous armor that is primarily metal and primarily rigid should be placed roughly around Tier 4 or Tier 5.

Armor Styles Tier 1: Cloth/Padded Armor

Tier 2: Light Leather · Butcher's Mail / Sharkmail

Tier 3: Heavy Leather · Chainmail · Rigid Non-Metal Armor

Tier 4: Light Scale

Tier 5: Heavy Scale · Butted Plate

Tier 6: Lamellar and Laminar · Brigandine · Plate

Special: Ambiguous Armor

Physical Armor Gameplay Rules · Construction Rules · Rating Armor & Calculating Armor Points · Armor Styles

Armor General Rules · Natural Armor · Physical Armor

Equipment Equipment Basics · Equipment Use Terms · Weapons · Shields · Armor · Color Code · Visual Indicators